Three Core Technologies

1. Instant Generation of NO

Novlead owns a series of core technologies for instant nitric oxide generation, facilitating the accurate and quick generation of high-purity nitric oxide gas with adjustable concentration and no harmful impurities in real time. It is suitable for a wide range of clinical scenarios for patients with pulmonary hypertension, pulmonary fibrosis and other indications, as a safe and reliable portable nitric oxide gas treatment source.

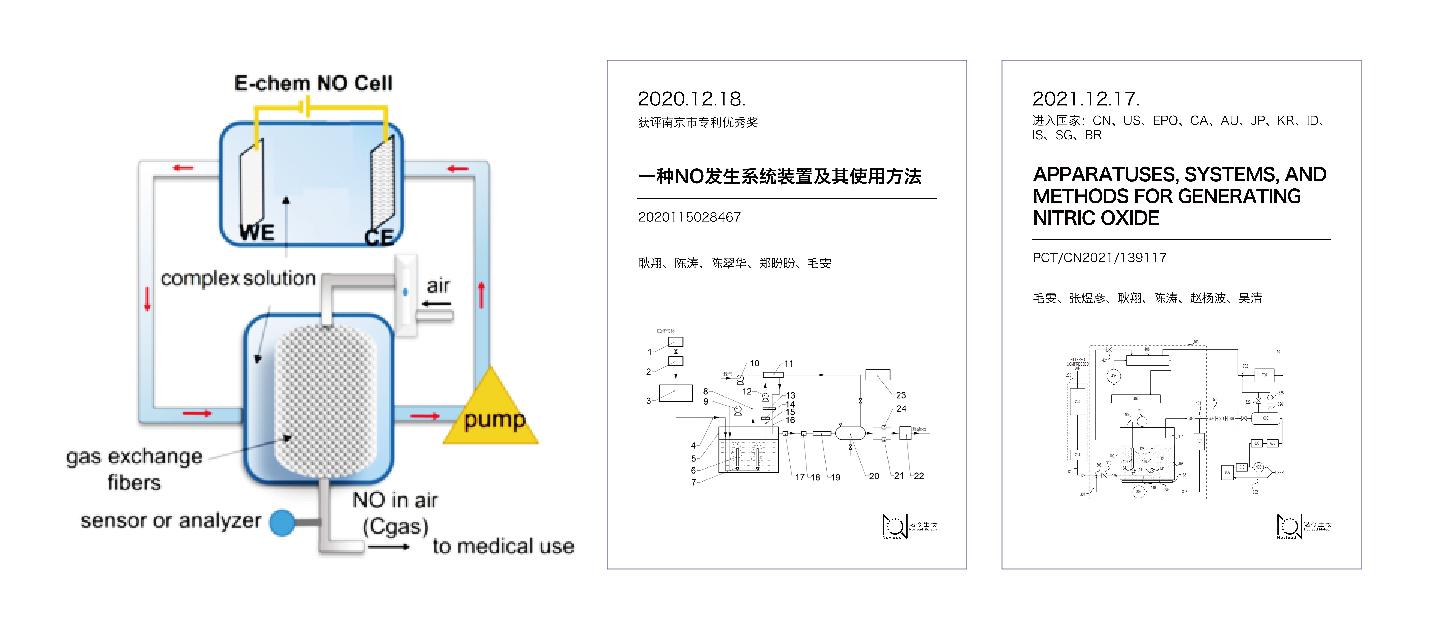

a. Instant Generation of NO---Electrochemical Catalytic Reduction:

NO generation technology uses transition metal ions having multiple valence states as the catalytic core. The metal ion in the high-valence state is changed to the low-valence state by a precisely controlled current, reducing the nitrite ion to NO. At the same time, the metal ions return to the high valence state and participate in the new round of reaction process.

● NO concentration can be precisely regulated by electric current, immediate, safe and controllable

● Pure NO gas with no by-products other than NO

● No high temperature or pressure needed, the gas is transferred always in room temperature

● Combined with highly efficient nitrogen generation technology, the NO generated uses nitrogen as the carrier gas, minimizing therisk of exposure to harmful byproducts such as NO2

b. Instant Generation of NO---High Temperature Plasma Air Conversion

By using high voltage, nitrogen and oxygen in the air are converted into high temperature plasma, where nitrogen and oxygen atoms recombine to produce NO, and also inevitably produce a small amount of NO2 and other impurities and trace metal particles. The specially designed filter contains a multiple filtration system to absorb impurities while effectively filtering particles to ensure the safety and purity of the user's gas.

● The reactants are taken from air directly, no storage, no extra charge for the feedstock

● The machine is small and portable, suitable for transit and other scenarios

● The filter is supported by a unique algorithm to ensure that the gas is effectively purified while the service life is extended as much as possible, and can be used for long-term stable treatment without frequent replacement

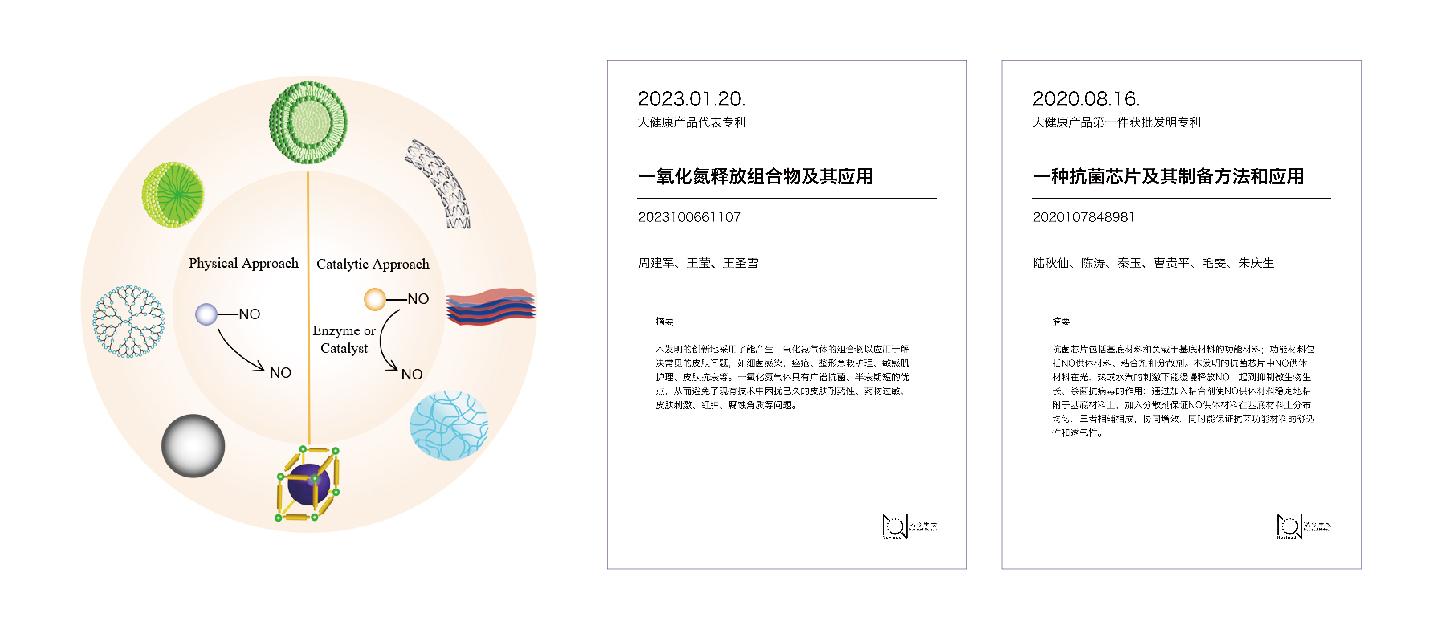

2. Controlled Release of NO

NO sustained release technologies are based on a variety of NO donors (compounds that release NO under specific conditions). Suitable materials can be provided through in-depth research on various donor molecule design, gas loading technology, sustained release condition control and process production, meeting diverse medical and consumer needs according to different application demand scenarios.

a. Design and Development of NO Controlled-Release Molecule

Based on the different requirements of NO action time and concentration required for vasodilatation, antibacterial and antiviral, engineered tissue regeneration, anti-aging, pain management, environmental disinfection, etc., according to the release mechanism and action path of endogenous and exogenous NO gas molecules, reasonable corresponding NO donor structure molecules are designed to ensure accurate and controllable release and use.

b. Gas Loading Technology

Combined with the molecular characteristics of different donor structures, inorganic nanoparticles, natural organic polymers, and organic porous membrane materials are used as gas carriers to achieve a high degree of integration of NO and the stability of donor structures for stable storage.

c. Control of Sustained-Release Conditions

According to the requirements of different application scenarios, the donor molecules and carriers are screened, and the sustained release conditions are controlled by adjusting the catalyst, light, sound wave, temperature, ph, etc., to achieve stable and on-demand release of NO gas in specific scenarios.

d. Consistent Process Requirements

Process verification of Class-10000 purification workshop, and continuous optimization of the whole production process of NO donor materials and products to ensure high purity and high quality of products, with minimal differences between product batches.

e. Various Product Dosage Forms

Based on the sustained release of NO technology, we develop diversified product forms, including liquid, paste, emulsion, gel, coating, granule, etc., involving Class I and II medical devices, disinfection products, cosmetics, etc., to meet the needs of different customers and different fields.

3. Gas Sensing Technology

Novlead is committed to providing advanced gas sensing technology, including electrochemical method and non-spectroscopic infrared method, to create a more accurate gas sensing technology system.

a. Electrochemical NO Gas Sensor ---- Ideal Choice for High Precision NO Gas Detection

● Fast response, with a unique electrode preparation process controlling the catalyst at the nanometer scale. This innovative design significantly improves the sensor's gas response speed, with a detection time of less than 15 seconds and ultra-high sensitivity. In addition, the precise production process ensures that the sensor still has good stability in different batches, ensuring the reliability of long-term use.

● High precision, with a unique circuit design, combined with a four-electrode electrochemical system, through filtering technology and advanced back-end algorithm, it greatly reduce baseline fluctuations. The sensor has a high resolution, can clearly detect the concentration of less than 5ppb gas, to provide users with accurate and reliable data support.

● Low interference, and the unique electrode design makes it highly selective for the target gas, significantly reducing interference from other gases. In addition, the sensor has a built-in high-efficiency filter, which can effectively filter common interfering gases such as sulfur dioxide and hydrogen sulfide, ensuring that flammability can provide accurate detection results in complex environments.

● High adaptability, Novlead’s NO electrochemical sensor adopts standard size, can easily fit with most exhaled breath detection equipment on the market, achieve plug and play, help customers quickly deploy applications.

With its fast response, ultra-high resolution, excellent anti-interference capability and good adaptability, Novlead’s NO sensor is a reliable choice for precision nitric oxide detection, suitable for a variety of demanding applications.

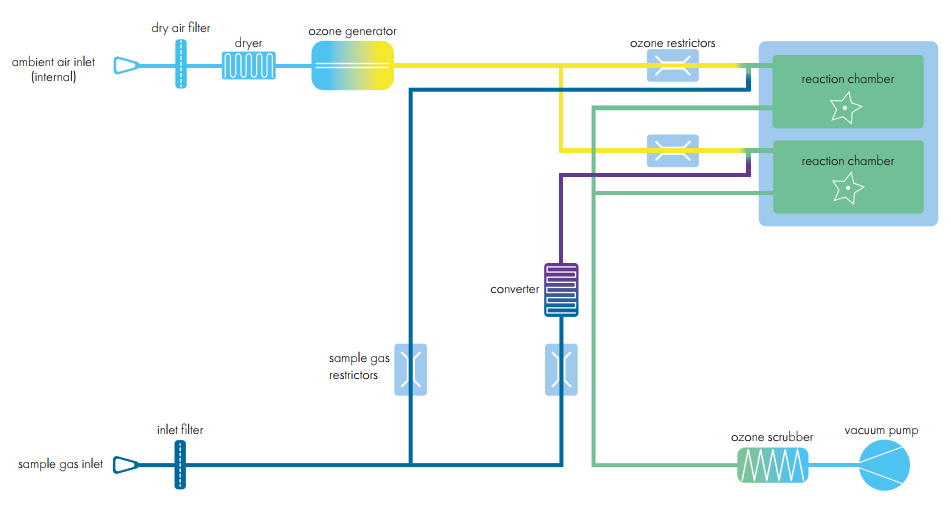

b. Non-Spectroscopic Infrared Method---Solution to Precise and Stable Gas Detection

● Fast response, NDIR technology uses an infrared light source and a lead selenide sensor, combined with a high-light-path gas chamber design, to achieve fast signal response, enabling quick response to instant changes in gas concentration, particularly suitable for applications with high requirements for real-time gas monitoring and control.

● High accuracy, with a specially designed gas chamber structure and surface treatment within the gas chamber, which effectively increases the optical path within a limited physical space, the sensor's response sensitivity to changes in gas concentration is thereby improved. Even in a compact design, the sensor remains highly accurate and sensitive to combustible gases, ensuring the accuracy of detection results.

● Real-time monitoring, using NDIR technology, combined with advanced algorithms developed in-house, results in a highly accurate and sensitive gas sampling module that can monitor the concentration of exhaled air in real-time, providing stable real-time data support for medical respiratory monitoring.

● The dual-channel technology, equipped with a dual-channel design for measurement and reference channels, can dynamically compensate for the effects of environmental variables and device aging on detection results. This technology greatly enhances the stability and long-term reliability of the sensor, ensuring that accurate data can still be output in complex environments.

NDIR spectroscopy technology, with its fast response, high accuracy, real-time monitoring, and dual-channel compensation advantages, provides precise and reliable solutions for various gas detection needs and is widely used in industrial control, medical detection, and environmental monitoring fields.